Digitalization

BySoft Suite: award-winning software brings all the processes together

Bystronic enables sheet metal processing companies to digitalize their processes: The new BySoft Suite allows our customers to interlink all their systems.

)

As a first of its kind in the world, our BySoft Suite convinced the expert panel at our industry’s leading trade fair in Europe: At EuroBLECH, the software took first place in the “Automation and handling” category.

In order to systematically implement digitalization, sheet metal processing companies require software that acts as an interface to the systems they already have. Our BySoft Suite makes precisely this possible. It can be used to integrate systems from third-party suppliers: The software is capable of interacting with business management systems as well as with machines from other manufacturers.

This means that the BySoft Suite offers our customers genuine added value:

- Our customers boost their efficiency by completely digitalizing their business.

- They benefit from interoperability as a result of the networking of all their systems.

- They improve their overview and streamline their workflows.

Six product families cover the processes

The BySoft Suite expands the popular BySoft software products that many of our customers already rely on.

The software suite consists of the six software product families Insight, Business, Shop Floor, CAD, CAM, and Cell Control. The comprehensive solution enables our customers to digitally monitor, manage, and analyze data throughout every phase of the business process – from the quotation all the way through to the shipping of the finished product.

The BySoft Suite gives customers greater control over their business. It allows them to manage their activities using a single platform. In addition, instant access to comprehensive information about all operations within their company allows them to accelerate their business. This allows our customers to more rapidly adapt to the ever-changing market environment and make business decisions based on extensive and centralized data.

One step closer to sustainability

Thanks to the BySoft Suite, our customers have the opportunity to digitalize their business and build a smart factory in which they have full control over all operations – regardless of their size or current level of digitalization. The technology offers a hybrid solution: It combines cloud and on-premises software, making it affordable even for small and medium-sized enterprises.

Here, digitalization and sustainability go hand in hand. Because the BySoft Suite helps our customers to achieve their sustainability goals. BySoft enables them to improve their energy and resource efficiency, resulting in reduced production waste, lower energy consumption, and more efficient material utilization.

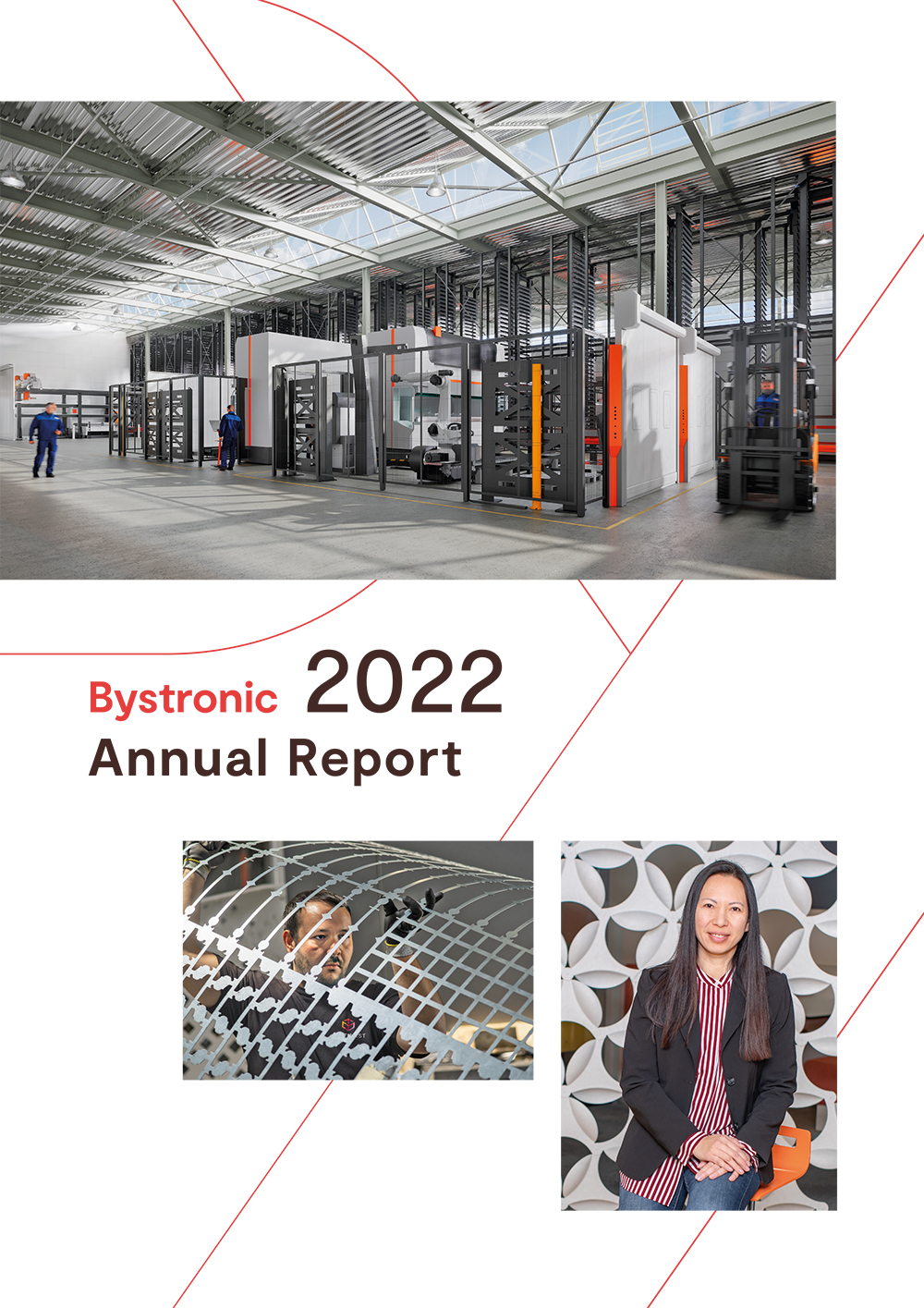

Smart factory: our vision for the networked shop floor

The digital transformation of our industry is in full swing. The vision is called smart factory – the completely networked shop floor. Intelligent software enables our customers to digitalize their processes and consolidate them in a single system.

Our smart factory system showcases how we envision the future of sheet metal processing: The data and material flow is completely networked and the processes are seamlessly connected – from the warehouse to production, right through to sorting. Everything comes together in an intelligent software system that controls production from a central location.

A vision becomes a reality: flagship project in the Netherlands

The future of sheet metal processing begins in Hapert near Eindhoven (Netherlands). There, VD Leegte Metaal is building a smart factory together with Bystronic: 99.5% waste-free cut parts, integrating machines from different manufacturers into the production environment, and the vision of Industry 4.0.

The smart factory solution for VD Leegte Metaal takes sheet metal processing to the next level. The two-year project represents a milestone in fully automated manufacturing. The main challenge for this flagship project is the software for the seamless integration of all components. The key factor for the success of the project was that we were able to offer a hands-on solution for all of VD Leegte Metaal’s specific requirements.

The sheet metal warehouse: the intelligent heart of the factory

The sheet metal warehouse consists of 37 towers with a total of 1,395 storage positions. These are accessed by two elevators. Each tower is 9.5 meters high. On the left side, the warehouse is equipped with four input-output stations. These can handle up to 24 metric tons of material per hour. On the right is the unloading station for the removal of cut parts, which can be removed using automated guided vehicles (AGVs). The material flow between the warehouse and the shop floor is self-organizing. The laser cutting machines request the raw material directly from the warehouse and return the cut parts as required. This applies both to Bystronic laser cutters and to third-party machines integrated into the solution.

The software: the brain of the smart factory

Bystronic’s Shop Floor Control Server makes it possible to manage the entire process flow from the file to the finished part, including intralogistics solutions. The programming of the bending cell is handled by two BySoft 7 Bending and Robot Manager controls. All software modules such as BySoft 7 Cutting, Plant Manager Cutting (PMC), BySoft 7 Bending, and Robot Manager are integrated in the latest system solutions.

Cybersecurity partnership with NanoLock

Bystronic has established a partnership with NanoLock. The reputable supplier of cybersecurity solutions is supporting us in protecting our systems against cyberattacks.

The increasing digitalization of our industry also creates new demands in terms of security. As smart factory solutions evolve, machines and systems are increasingly being connected to the cloud, to software systems and robots, automation solutions, and other machines. Cybersecurity is thus becoming a challenge, because this connectivity also opens up new vulnerabilities for cyberattacks.

Our new partnership in the field of cybersecurity assures the operational integrity of our machines. The solution, developed together with NanoLock, prevents unauthorized changes to critical content without compromising performance or functionality. The solution protects against cyberattacks both from external sources and from trusted ones, as cybersecurity incidents are often the result of employee carelessness and human error. In addition, we are also planning to provide online monitoring and analytics services.