Strategy

Innovative technologies for sheet metal processing

Bystronic is an industry leader

As a global leading technology company in sheet metal processing, Bystronic offers innovative laser cutting systems and press brakes as well as automation, software and service solutions. When it comes to cutting and bending sheet metal parts, our customers depend on the high quality, precision and efficiency of our systems.

Since its founding 35 years ago, Bystronic has made innovation its top priority. Today, we have nine development and production locations in Switzerland, Germany, Italy, China and the USA. Our network includes sales and service subsidiaries in more than 30 countries, as well as representative agents in additional countries.

Our portfolio is structured into three market segments: gold, silver, and entry-level. The products in these three groups differ primarily in terms of laser power, speed, degree of automation and additional features. This allows us to comprehensively meet the varying needs and budgets of our customers.

Sheet metal is an appealing material with a bright future

From agriculture and construction to the transport and food industries, almost every sector relies on sheet metal. The material is tried and tested, versatile in its applications, and offers numerous advantages. Metals such as steel or aluminum are robust, easy to handle, durable and recyclable. Without a doubt, sheet metal will remain a key building block in many different industries in the future. At the same time, new processes that do not rely on fossil fuels help make steel production more sustainable and contribute to the continuous improvement of the material's carbon footprint.

Our customers work in a variety of end markets

Our customers produce sheet metal parts either as contract manufacturers or for their own portfolios. Customers with their own portfolios are either original equipment manufacturers (OEMs), or they sell the parts they manufacture for subsequent finishing. Since sheet metal is a material with very diverse applications, Bystronic's customers are active in a variety of end markets. The parts produced with our systems are used, for example, in kitchen appliances, construction machinery, solar installations and wind turbines. Demand in these markets develops very differently depending on economic trends. Broad diversification in end markets reduces our dependency on economic trends and makes our business model more resilient.

Our strategy: growth across systems, service, and software

The Bystronic strategy is based on the growth areas of systems, service and software. In all three areas, we are positioned well to expand the business and increase market share.

In the area of systems, our innovative portfolio of products serves as a crucial driver for our growth. Bystronic generates almost half of its sales with products that have been on the market for less than three years. This demonstrates our innovation strength and shows how quickly our portfolio is expanding. In addition to offering established laser cutting and bending machines, we are focusing on automation solutions, for example for loading and sorting equipment. We are also consistently implementing our regionalization strategy, which calls for us to support our customers locally. On the one hand, we operate closer to where customers require us in their regions. On the other hand, local supply chains can provide faster and more reliable delivery.

In the area of service, we are enhancing structures, expertise and the workforce to promote our service business. Regular machine maintenance is crucial for our customers' productivity. Operational interruptions must be avoided as much as possible. To minimize down time in line with customer requirements, we offer a modular, globally standardized service program. This allows customers to select annual contracts with different services. The modules include, for example, the number of visits from service technicians, specific service level agreements, or warranty services. Since the program launched in early 2021, more than 90% of machines sold in our gold and silver segments included a service contract.

In terms of software, we are supporting our customers as they move their production in the direction of a Smart Factory. Many production plants are currently looking for ways to comprehensively network and control their production using software. Our solutions enable sheet metal processing companies to digitalize their production processes. We offer, for example, software modules for preparing quotes or for monitoring machine performance. Offering individual modules allows the customer to gradually augment their degree of digitalization, thereby achieving significant productivity improvements. We accompany our customers through their digital transformation one step at a time.

Our Markets

Close to our customers

Our country subsidiaries around the globe are crucial components of our regionalization strategy, which allows us to meet local requirements optimally.

One large emerging market is India, where we have had representation through a subsidiary since 2007. In recent years, the Indian manufacturing industry has grown rapidly due to the expansion of public infrastructure and India’s improved connections to world markets. As there is a shortage of skilled workers, companies are looking for manufacturers that provide automation and have well-trained service technicians. Bystronic India therefore concentrates on providing cost-efficient solutions with higher operating times and productivity. To be even more closely engaged with the Indian sheet metal industry, we opened a new business office in the summer of 2023 in Pune, 150 kilometers southeast of Mumbai. This facility has a state-of-the-art demonstration center where we can present our solutions to customers.

)

We are also moving closer to our customers in China. In summer 2023, the region conducted its own Competence Days and presented product innovations. This included, for example, the automatic loading and unloading systems ByTrans Eco and ByTower Eco. Both systems are an indispensable part of the path to a highly productive Smart Factory.

)

Our focus is on the customer

Bystronic makes a clear claim: Our systems, services, and software solutions are meant to heighten productivity, efficiency and sustainability in the sheet metal industry. The design of customer interaction is a critical component of this. Our specialists – be they sales experts, service technicians, or service hotline operators – need to be knowledgeable about the customer’s current on-site situation: Which machines does the company operate? When was our last engagement with the customer? What upcoming maintenance work should be considered? Such information must be fully available at all times when communicating with customers. That is the only way to ensure that each subsequent communication ties seamlessly with previous contacts.

The foundation for such seamless communication is an effective customer relationship management (CRM) system. In late 2021, we decided to introduce the most modern CRM solution on the market for this purpose. We made the following improvements:

- To ensure that all information is available anytime to our customers and to us internally, we operate a system environment that is completely integrated and allows optimal data exchange between marketing, sales and service.

- The customer can choose how to contact us – through a sales representative, by telephone, or online. This allows us to communicate consistently in line with our motto “One Bystronic.”

- To ensure that the processes are optimally tailored to customer needs, we review all processes and make improvements during the installation.

A project team consisting of employees from the sales, service, marketing, IT, procurement and finance departments, as well as external partners, managed to launch the CRM system in less than 16 months, from solution definition all the way to launch. The successful introduction ensures that we will continue to think about our products and services from the customer’s perspective in the future.

Innovation and Technology

Launch of a new product platform

To configure machines better for customer applications and to produce them faster and locally, we have developed a new platform concept: All systems for a specific application such as cutting or bending are now based on a single platform. From this uniform starting point, we can produce various machines and formats in configurations for both our gold and silver segments. This simplifies the product creation process, from development, procurement, and production right through to training and system maintenance. This enables us to reduce manufacturing costs while also enhancing the reliability of our machines.

In 2023, production based on this new concept began. For the first time, last summer the team in the USA, using the new platform, locally assembled and completed machines for the gold segment.

New products

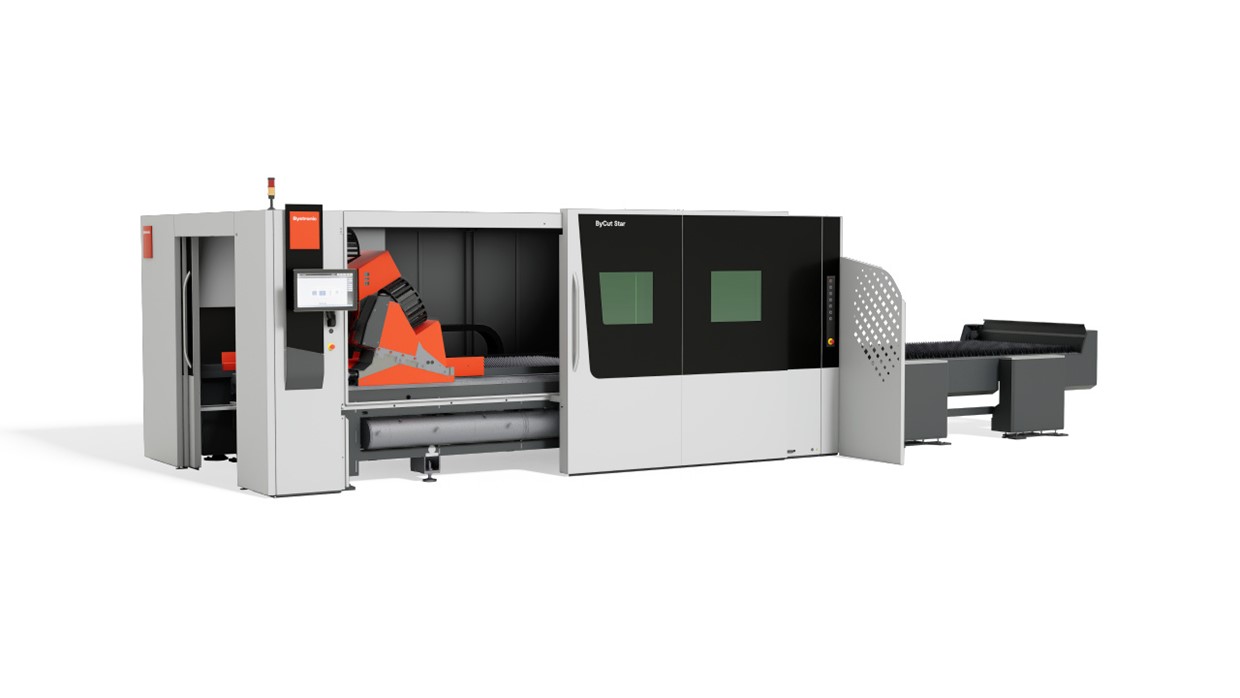

The laser power of cutting machines has made great advancements in recent years. Bystronic is involved at the forefront of the advanced development of fiber laser technology. Two years ago, we presented the ByCut Star 4020, a laser cutting system from the gold segment with a laser power of 30 kilowatts, currently the highest level of power available. This machine is already based on our new product platform; now we can quickly derive new formats from it.

In 2023, we launched the ByCut Star 3015, which likewise has a peak power of 30 kilowatts and is designed specifically for sheet metal with dimensions of 3 × 1.5 meters. The machine features our newest smart features, such as the Intelligent Cutting Process ICP. With this, a camera films the cutting process through a nozzle. The system automatically detects interruptions in the cut and recuts the area if necessary. In addition, our latest products come in a new design that makes them more user-friendly. This includes new front and/or side access, as well as multiple windows with direct views of the cutting process. The interior is significantly more accessible as a result.

Digitalization

Implementation of our Smart Factory solutions

With our modular software offerings, we enable our customers to network all of their processes and thus ultimately implement the Smart Factory vision. This requires software that acts as an interface to the systems they already have. This is precisely what the BySoft Suite makes possible. It consists of six software product families: Insight, Business, Shop Floor, CAD, CAM, and Cell Control. The integrated solution allows our customers to digitally monitor, manage and analyze data through every phase of the business process – from quotation to shipping of the finished product. Machines from third-party suppliers and IT solutions for business management can also be integrated into the software. Sheet metal processing companies can thus manage all their activities using a single platform and access comprehensive information about all enterprise operations at any time. This allows them to adapt more rapidly to the ever-changing market environment, make business decisions based on extensive and centralized data, improve productivity and grow, despite a shortage of skilled workers.

Our customers are using the BySoft Suite to advance digitalization. The Dutch company VD Leegte Metaal completed its Smart Factory in Eindhoven toward the end of 2023. The two-year project is a milestone in fully automated production. The main challenge for this flagship project was the software to completely network all components, including systems from competitors. The material flow between the warehouse and the shop floor happens automatically. Laser cutting systems and press brakes automatically order raw material from the warehouse, and automated guided vehicles (AGV) transport the materials to production stations. The BySoft Suite facilitates the management of the entire process, from the drawing to the finished part, including intralogistics solutions.

)